Material Testing Lab Excellence: Unveiling the Tricks to Job Toughness

Wiki Article

Developments in Material Screening for Boosted Quality Control

From non-destructive testing strategies to automated systems, the area of material testing has actually seen remarkable advancements. In this conversation, we will explore some of the most current patterns in product testing, consisting of the use of innovative sensing unit innovations, the combination of information analytics, and the role of fabricated knowledge. Allow's dive right into the globe of improvements in product screening and uncover how these advancements are forming the future of top quality guarantee.Non-Destructive Evaluating Approaches

Non-Destructive Testing Methods play a vital duty in guaranteeing the honesty and top quality of products without endangering their architectural stability. These techniques are utilized in different markets, consisting of aerospace, construction, and manufacturing, to find and recognize flaws or anomalies in materials or structures. By utilizing non-destructive testing techniques, designers and technicians can evaluate the residential properties, qualities, and performance of products without causing any kind of damages.One generally used non-destructive screening method is ultrasonic testing (UT) UT involves the usage of high-frequency sound waves to detect problems such as cracks, spaces, and incorporations in materials.

Non-destructive testing techniques supply valuable information about the quality and reliability of materials, making sure that they fulfill the needed specs and requirements. By carrying out these strategies, industries can enhance their quality assurance procedures, decrease the risk of failing or crashes, and inevitably supply more secure and more reliable products to customers.

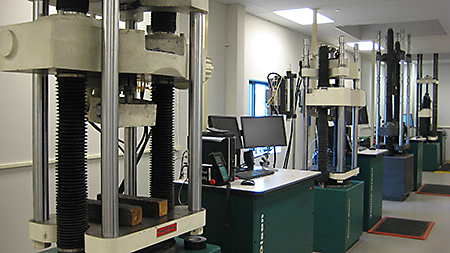

Automated Testing Solutions

Automated testing systems have transformed the field of product screening, offering exact and efficient methods for reviewing the top quality and honesty of materials. These systems utilize innovative modern technologies and algorithms to automate the screening process, reducing human mistake and raising performance.One secret benefit of automated testing systems is their capacity to perform tests at a much faster price than manual screening approaches. With making use of robotics and advanced software, these systems can conduct several tests concurrently, substantially decreasing the moment needed for screening big batches of products.

Additionally, automated testing systems supply a higher degree of precision and precision compared to manual screening. They can carry out tests with constant specifications, making certain that the results gotten are reliable and reproducible. By getting rid of human subjectivity and variability, these systems provide a much more objective analysis of material top quality.

In addition, these systems are furnished with innovative sensors and detectors that can identify also the smallest flaws or deviations in product properties. This enables early detection of possible issues, permitting producers to take rehabilitative actions prior to the products are used in crucial applications.

Along with their performance and accuracy, automated testing systems additionally improve safety and security in material testing. By decreasing human participation in potentially dangerous screening treatments, these systems decrease the danger of injuries and crashes, making certain a more secure working atmosphere.

Advanced Sensing Unit Technologies

With the assimilation of cutting-edge sensor modern technologies, material screening systems have actually attained also greater levels of precision and effectiveness (material testing lab). Advanced sensing unit modern technologies play an important duty in enhancing the quality assurance process by offering accurate and real-time information throughout product screening. These sensing units are qualified of spotting and determining different physical homes such as temperature, stress, pressure, and vibration, permitting a thorough evaluation of the product's habits under different conditionsOne of the vital advancements in sensing unit modern technologies is the development of cordless sensing units. These sensing units remove the demand for difficult circuitry and enable smooth information transfer, enhancing the general versatility and mobility of the testing process. Moreover, wireless sensors can be quickly you can try this out integrated right into existing product testing systems, making them an affordable option for updating and enhancing testing capacities.

Expert System in Material Testing

Expert system has actually reinvented the field of product screening, bringing unprecedented levels of precision, efficiency, and predictive capacities to the quality control process. With the capability to examine huge quantities of information and determine patterns that might go undetected by human operators, AI algorithms have actually significantly boosted the reliability of material screening treatments.Among the key benefits of making use of AI in product testing is its capability to forecast material habits under various problems. By educating AI versions on historical information, scientists can create anticipating models that can approximate the performance of materials in real-world scenarios. This enables makers to optimize product option and design, decreasing the requirement for expensive and time-consuming experimental procedures.

In addition, AI can simplify the product and automate screening procedure, boosting performance and minimizing human mistake (material testing lab). AI-powered systems can autonomously accomplish testing treatments, accumulate and assess information, and produce detailed records. This not just conserves time yet additionally makes certain reputable and consistent results

Furthermore, AI can spot and analyze material defects or abnormalities with high accuracy. By comparing test results to predefined requirements, AI formulas can swiftly determine discrepancies and alert drivers to prospective concerns. This very early detection of defects aids stop defective products from going into the production procedure, inevitably enhancing product quality and client contentment.

Combination of Information Analytics

Information analytics plays a vital function in the combination of material screening procedures, allowing manufacturers to remove useful understandings and make informed choices. By utilizing innovative analytic methods, producers can evaluate large quantities of data gathered during product testing to determine patterns, trends, and anomalies that might affect the top quality and performance of their items.Integration of data analytics in product testing permits makers to keep track of and review various parameters and variables throughout the testing process. This see here consists of factors such as temperature, stress, strain, and various other ecological problems that can influence the habits and features of materials. By examining this information, suppliers can acquire a much deeper understanding of just how various variables communicate and influence the performance of their materials.

Additionally, data analytics helps in recognizing prospective flaws or weak points in products, allowing makers to take aggressive procedures to deal with these problems before they cause item failings or safety dangers. This proactive approach can dramatically boost the general top quality guarantee procedure and improve client complete satisfaction.

In enhancement to identifying defects, data analytics can also optimize product testing procedures by identifying areas of improvement and recommending alterations in the testing protocols. By evaluating historical information, suppliers can identify patterns and trends that can help them streamline their screening procedures, lower prices, and improve performance.

Verdict

Non-destructive testing approaches, automated testing systems, advanced sensing unit innovations, and the integration of information analytics have all played a significant function in improving the precision and effectiveness of product screening processes. Additionally, the application of artificial intelligence in material testing has additionally added to the development of even more trusted and accurate testing techniques.From non-destructive testing techniques to automated systems, the field of material screening has actually seen amazing developments. Wireless sensors can be easily integrated into existing product testing systems, making them a cost-efficient solution for upgrading and improving testing capabilities.

Assimilation of data analytics in material screening permits makers to check and evaluate numerous parameters and variables throughout the screening procedure. Non-destructive testing techniques, automated testing systems, progressed sensor technologies, and the combination of information analytics have all played a significant duty in enhancing the accuracy and effectiveness of product screening processes. Additionally, the application of artificial knowledge in material screening has further added to the growth of even more reputable and specific screening methods.

Report this wiki page